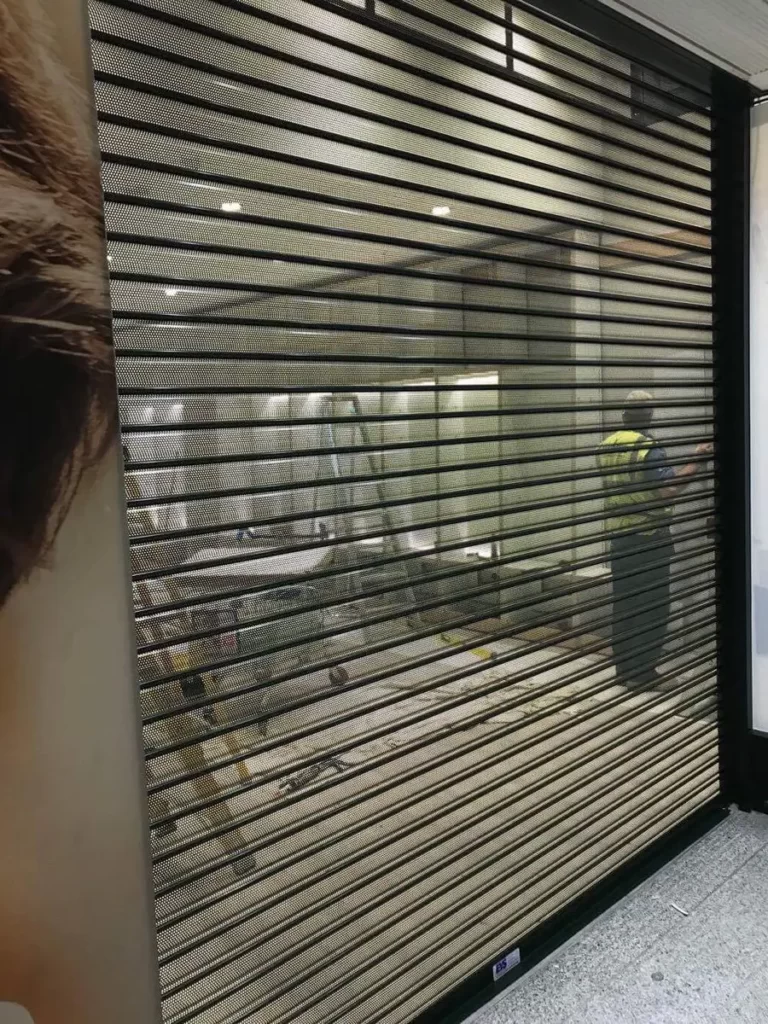

Perforated Roller Shutters

Perforated Roller Shutters System

The perforated type of shutter offers the best compromise between visibility and security. With thousands of small holes a brightly lit window display is still visible but the holes are too small to allow object through. Perforated security shutters provide a transparent effect when background lighting is illuminated. This particular design of shutter offers a high degree of security with inner integral strength. Perforated shutters are commonly used when ventilation is a requirement.

Features of Perforated Roller Shutters:

- Perforated roller shutters offer a high level of security, protecting your property from break-ins, vandalism, and unauthorized access.

- The perforations in the shutters allow for controlled airflow and natural light to enter the building. This makes them suitable for spaces where ventilation and visibility are essential, such as retail stores or showrooms.

- Perforated shutters can help regulate the temperature inside a building. They allow for airflow, preventing the space from becoming too hot or stuffy in warm weather while also providing insulation in colder months.

- Perforated roller shutters are typically made from durable materials like aluminum or steel, making them resistant to weather conditions and wear and tear.

- The shutter's construction and the material used can contribute to noise reduction, making them suitable for areas with high noise levels or for businesses that require a quiet environment.

- They are relatively low-maintenance, requiring periodic cleaning and occasional lubrication for smooth operation.

- For businesses with a storefront, perforated roller shutters can serve as an advertising space when they are closed, helping increase brand visibility and potentially attracting customers.

Specifications of Perforated Roller Shutters:

- Material: Perforated roller shutters are often made from durable materials such as aluminum, steel, or stainless steel. The choice of material can affect the shutter's strength, resistance to corrosion, and overall durability.

- Perforation Pattern: The perforation pattern refers to the arrangement and size of the holes or slots in the shutter curtain. Different patterns offer varying levels of visibility, airflow, and security. Common patterns include circular, square, or slotted perforations.

- Curtain Thickness: The thickness of the shutter curtain can impact its strength and insulation properties. Thicker curtains may provide better security and insulation but can also be heavier.

- Finish and Color: Perforated roller shutters can be finished with various coatings or paint colors to match the aesthetics of the building or storefront. Powder coating is a common finish option for added durability and resistance to weather.

- Size and Dimensions: The size and dimensions of the shutter should be customized to fit the specific opening it will cover. Shutter width, height, and roll diameter are essential considerations.

- Security Features: Some shutters may include additional security features such as locking mechanisms, anti-lift devices, or tamper-resistant components.

- Safety Features: Safety features can include photoelectric sensors or safety edges to prevent accidents or entrapment during operation. Compliance with safety standards and regulations is crucial.

The Perforated Roller Shutters framing systems are powder coated to the highest standard, with a range of over 200 polyester powder paint colours available in a gloss, matt or satin finish, to match your individual taste or to suit corporate or brand requirements.